LOWA Boots are 100% produced in Europe.

At Appalachian Outfitters, we’re constantly working to provide our customers with the best products available, which means partnering with innovative brands from all over the world. We’ve been representing the LOWA brand at our store for a while now, but recently we’ve been given the opportunity to create a LOWA concept store with the European brand.

The LOWA Concept Store allows us to partner with the brand to display some of the outdoor market’s highest quality outdoor shoes and boots. At the display, we’ll have a detailed demonstration of LOWA’s product line for Ohio’s outdoors enthusiasts. This will give customers access to a wider range of LOWA products than ever before, including more styles and sizes.

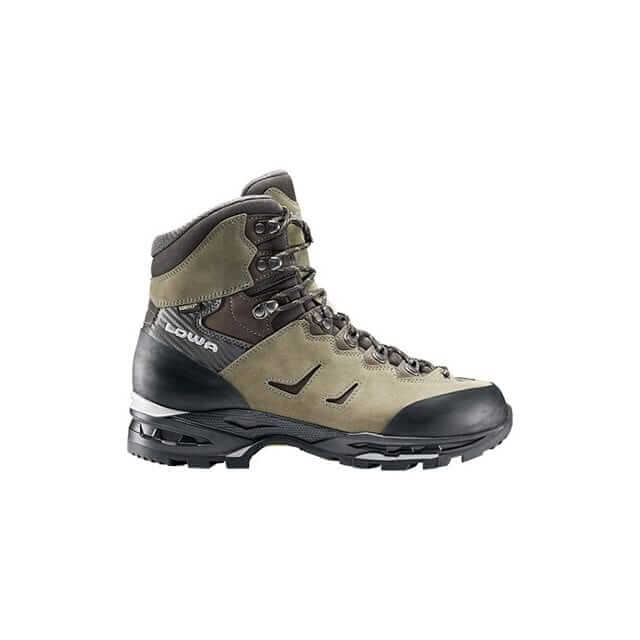

LOWA Boots are made of the highest quality European cow leather.

Once we were sold on the idea of a concept store, representatives from LOWA brought in nearly 30 different styles of LOWA shoes to get a closer look at. We held multiple meetings with our LOWA regional sales representative as well as LOWA USA General Manager. These meetings helped us pinpoint the choice of boots and shoes that best fit our customers in Northeastern Ohio.

LOWA Boots have polyurethane soles for extra support and durability

One of our favorite things about LOWA is the company’s dedication to manufacturing 100% of its products in Europe. This enables the team to supervise the entire production process, guaranteeing that LOWA gear has much higher quality than other companies that outsource production to other regions.

From start to finish, the main highlights of the LOWA production process looks like this:

- Materials: The highest quality products start with the highest quality materials. LOWA uses only the best pollutant-free leather from European cowhides and tans the leather for more durability. Leather is resistant to abrasion but still flexible, maintaining the shape of the shoe while being worn and stretched. LOWA designers tan leather using the most environmentally responsible process, with the tanneries operating their own wastewater treatment plants.

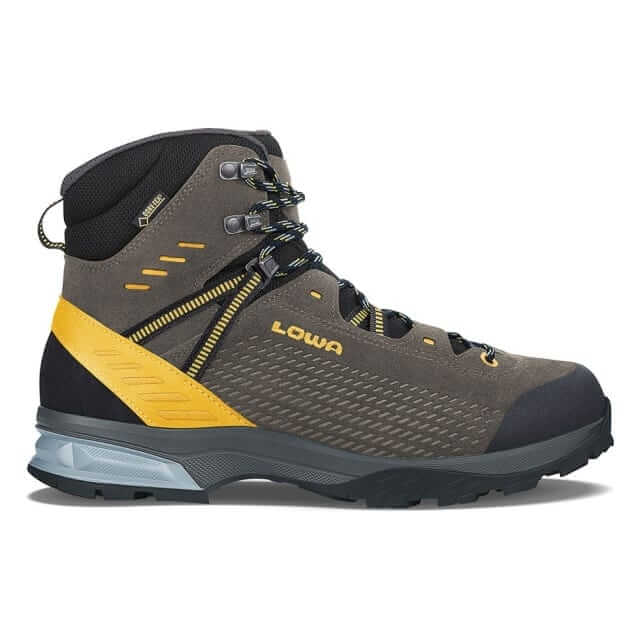

- Suitability: It’s important to choose the right leather for the right part of the shoe. Smooth leather, taken from the hide’s upper layers, is more susceptible to scratches. Nubuck leather can be lightly brushed to make it somewhat scratch resistant but more durable, perfect for trekking boots. Suede/split leather, from the hide’s middle layers, is very durable; it doesn’t stretch very well and holds strong against tears. Roughout/hunting leather has a tough surface for the best Alpine boots.

- Design: After the leather is tanned and chosen for the shoe, a hydraulic press punches cuts into the leather. The mechanical pattern-cutter is needed for each shoe, dictating the design and size. The most important part is putting the pattern-cutter on the right kind of leather, punching the pattern for the best flexibility and durability of the shoe.

- Putting It Together: Once the pieces are cut, they are sewn with machines. GORE-TEX® lining is added to the seams for reinforcement. Then LOWA designers use the company’s unique gluing process to make certain the leather pores are sealed against moisture. With riveting machines, they add the metal hooks and eyelets for the laces.

- Last: Lasts are the wooden or plastic foot-like forms where the rest of the shoe is made. The shoe is molded onto the last to meet the design for the specific shoe’s feel and fit, making the shoe exactly what you’re looking for. Each style of shoe has a unique last. The designers use computer operated machinery guides to put the leather upper onto the last. The sole is at the bottom of the last, so the machine pincers use tacks or cement to attach the leather to the insole. Later in the process, the outsole will be added to this insole, which will make the shoe or boot stiff or flexible, depending on the style.

- Sole: One of the unique things about LOWA is the rubber rand, which is a protecting edging that is separately added on the outside of the shoe. It keeps the shoe resistant to damage and moisture. Designers attach the rubber sole with its cushioning polyurethane foam midsole. This sole is pretreated and then cemented onto the shoe with a pneumatic press.

- Final Touches: Now machinery takes the shoe off the last. The laces at woven through the eyelets and hooks, footbeds are added, and tags are tied onto the shoes. Then the footwear is placed in boxes and mailed to eager adventurers like you!

LOWA Concept Store With Appalachian Outfitters

LOWA Boots are built to last through whatever you may face in the outdoors.